Qu'est-ce qu'un système de quincaillerie pour porte-fenêtre ?

07 Sep, 2022window door hardware is the general name of various metal and non-metal accessories installed on building doors and windows, which plays an auxiliary role in opening and closing doors and windows. The surface is generally plated or coated, which is strong, durable, flexible, economical and beautiful.window door hardware can be divided into opening and closing parts, bearing parts, operating parts and auxiliary parts. Through the matching and integration of the system, it serves the subsystems of......

Panne de machine de fenêtre en aluminium à rupture de pont thermique

10 Sep, 20211. The thremal break aluminum window machine has a long working time. Due to the needs of production, some users’ industrial control systems need to work for a long time, which brings a huge load to the operating system of the door and window equipment. The internal temperature of the thremal break aluminum window machine is too high. In the environment of high temperature operation, the components in the equipment are in a high temperature state for a long time. If they are not cooled in tim......

Détails de débogage de la machine de portes et fenêtres en aluminium

01 Sep, 2021First,in terms of electricity.Voltage 380V is the normal voltage of general door and window machinery, and the frequency is 50Hz. Therefore, the connection between the live wire and the neutral wire needs to be paid attention to. The live wire and the neutral wire must be connected well, otherwise it may cause an accident. Generally speaking, most door and window equipment manufacturers distinguish by color,the live line is black or blue, and the zero line is red. If the live wires are reversed,......

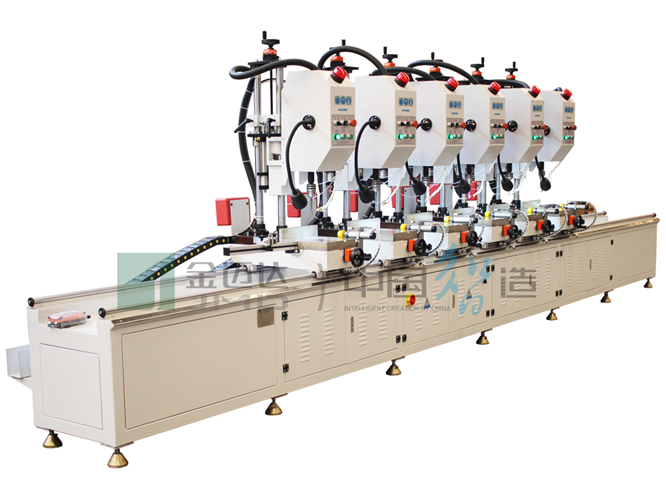

À propos de la perceuse multi-têtes

11 Aug, 2021This machine adopts 6 set drilling head, each head adopts three-axis drill pack for drilling holes, which can be combined to use according to the hole diameter on the drilling bit rocker arm and center distance. Six sets drilling head was installed on the bed guide rail,which can move right-left and pneumatic locking arbitrarily;Six sets drill bit drilling holes can be either single action or linkage, especially fit for mass production;Head feeding adopts cylinder and damping cylinder, which ......

Cinq avantages des portes et fenêtres en aluminium à rupture de pont thermique

28 Jul, 20211. Energy saving and environmental protection Thermal break aluminum doors and windows have good airtightness. In the hot summer, the indoor temperature is often higher than the outdoor temperature. If the doors and windows inside the home are not sealed well, the indoor temperature will drop relatively slowly, and the air conditioner will be turned on. The time will be longer. So on the contrary, if the doors and windows of the house are tightly sealed, the indoor temperature will drop fast......

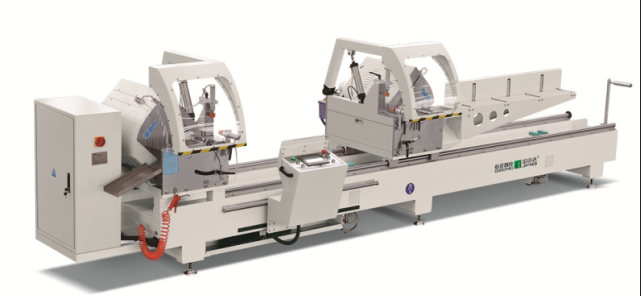

Avantages de la scie à double tête en aluminium

23 Jul, 20211. The double-head cutting saw is a profile cutting tool used in the production of doors and windows. It is suitable for cutting aluminum and plastic profiles. The transmission and feed of the sawing machine are controlled by a numerical control system. The cutting size has high precision, simple operation, reliable performance, and advanced technology. The cutter adopts cemented carbide circular saw, which has fast cutting speed and high production efficiency. It is an ideal equipment for the ......

Comment juger de la qualité des machines pour portes et fenêtres en aluminium ?

23 Jun, 20211. From the point of view of materials, the thickness, strength and oxide film of high-quality aluminum door and window machinery should meet relevant standards. The wall thickness should be greater than 1.2 mm, the tensile strength should reach 157 Newtons per square millimeter, the yield strength should reach 108 Newtons per square millimeter, and the oxide film thickness should reach 10 microns. If it does not meet the above standards, it is a low-quality aluminum alloy door and window equip......

Quel équipement est nécessaire pour ouvrir une usine de portes et fenêtres

11 Jun, 20211. Double head cutting sawThe double-head cutting saw is used to cut aluminum alloy profiles. The accuracy of sawing directly affects the quality of doors and windows, so double-head saws are essential equipment for the production of doors and windows. There are many varieties of double-head cutting saws on the equipment market. For example: Manual, digital display, CNC. Specially cut 45 degrees, there are also 45 degrees and 90 degrees. The price ranges from tens of thousands to hundreds of th......

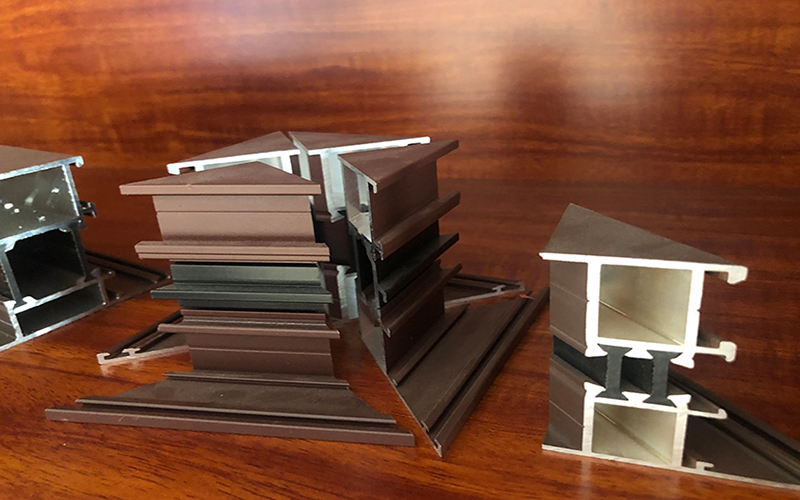

Comment choisir les portes et fenêtres en alliage d’aluminium ?

28 May, 2021First understand the classification and advantages of aluminum alloy windows. Aluminum alloy windows are the first products to replace steel windows. They are made of aluminum alloy extruded profiles as frames, stiles and fans. Ordinary aluminum alloy sliding windows use aluminum alloy as the main material, and have better sealing and sound insulation effects than steel windows. It is also easier to process than pure wooden windows and steel windows. 1. Classification of aluminum alloy windo......

Quels sont les outils utilisés pour fabriquer des portes et fenêtres en aluminium ?

25 May, 2021Double-head mitre saw: used for cutting profiles to make aluminium doors and windows, According to the size of the aluminium doors and windows, cut the main profile at the required angle. The main angles are 90° and 45°. JMD has two types of double-head saws, CNC double-head saw and digital display double-head saw. (1) CNC double head saw features: 1.Schneider CNC system & automatic profile supporting system.2. Driven by rack, the right machine head horizontally moves with pr......

Combien coûte une fenêtre en aluminium ?

14 Mar, 2021There are three main factors that affect the price of aluminum alloy windows and doors: brand models of aluminum profiles, hardware accessories, and the number of purchases. Why are these three points the main factors that affect the price of aluminum alloy windows? because these three points directly lead to high and low prices of aluminum alloy windows. The brand models of aluminum profiles range from 400 yuan per square meter in 55 series to 600 yuan per square meter in 70 series, and the wa......

Qu'est-ce que la scie à découper pour connecteur d'angle CNC ?

04 Mar, 2021Angle code saw is a professional door and window cutting equipment used by door and window processing enterprises to cut aluminum angle code when producing broken bridge aluminum doors and windows. at present, it is mainly divided into heavy automatic angle code cutting saw, semi-automatic angle code cutting saw and numerical control angle code cutting saw.1. Schneider CNC system; Cable & electric wires: YiChu; Pneumatic components: AirTAC; Saw blade: Janpan DaHe2. Profile feeding driven by ......

Pourquoi le prix de la même machine en aluminium n’est-il pas le même ?

17 Dec, 2020No matter in the domestic or international market, there is a huge difference in the price of aluminium window machinery with the same function. What is the reason for this phenomenon? Jin Maida will explain it to you in detail: First, brand, aluminium window making machine for sale the price of equipment with the same function varies from brand to brand. The brand value of domestic aluminum door and window equipment is gradually being established. with the rapid development of door and windo......

Comment fabriquer des fenêtres en aluminium ?

10 Dec, 2020There are many kinds of doors and windows. According to the materials, we can divide them into aluminum windows, UPVC windows, and wooden windows. According to the opening mode of windows, they can be divided into open windows, sliding windows, downward rotating windows and so on. We will explain how to make aluminum open windows and the making process.Let's take a look at the aluminum windows production flow chart(1) Prepare materials. To know the specifications windows, and then prepare the c......

Comment entretenir la machine à sertir les coins des portes battantes en aluminium ?

16 Sep, 20201. Before the equipment is used, the inspection and maintenance of the equipment shall be done well. The transmission part of the equipment shall be frequently filled with lubricating oil to keep the oil quantity sufficient, so as to avoid the jamming caused by insufficient lubrication and affect the angle setting effect of the angle setting machine. 2. The working medium of the oil pump is hydraulic oil. Keep the oil volume on the middle line of the oil mark to prevent the oil pump from ......

Problèmes et méthodes auxquels il convient de prêter attention lors du traitement d'emboutissage de

15 Sep, 2020Because the aluminum alloy stamping material is softer than metal iron, the price is expensive, it is easy to break, and some aluminum alloy products need follow-up processing, such as wire drawing, anodic treatment, etc., it is especially easy to produce top injuries and scratches during stamping production. Special attention should be paid to the following points in die manufacturing: 1. Punching should be arranged at the back of the project as far as possible without affecting the number of ......

Machine de sertissage d'angle hydraulique robuste (LJZJZ-150)

15 Sep, 2020Corner crimping machine is one of crucial machines for making windows. This type has many advantages as follows which may be suitable for you.1. The max driving force is 7 -8 tons which can crimp thicker and heavier profiles easily.2. The positioning body、blade seat and base plate are made by ductile casting iron which have high abrasion resistance and good rigidity.3. The positioning head of the crimping blade adapts wire cutting,the blade seat are equipped by the scale which is convenient......

Maintenance des équipements de traitement des alliages d'aluminium

14 Sep, 2020The maintenance of aluminum alloy processing equipment generally includes daily maintenance, regular maintenance, regular inspection and accuracy inspection. The daily maintenance of aluminum alloy processing equipment is the basic work of equipment maintenance, which must be institutionalized and standardized. For the regular maintenance of aluminum alloy processing equipment, work quota and material consumption quota shall be formulated and assessed according to the quota. The regular ......